Revolutionize your livestock feed inventory management with BinConnect

Request a demo

Business challenges

Are unplanned empty feed bins a daily concern for you?

Rushed planning changes

Empty feed bins

Last minute deliveries

Unnecessary overtime

Do not let unplanned empty feed bins disrupt your operations again

Solution

This is how we solve your problems

Fill level & forecast

Whether you are on the farm, in an office or on vacation, monitor inventory up to 4 days ahead

Automated alerts

Easy ordering tool

Implementation

Improve operations with BinConnect's practical solutions

A simple sensor for big gains

Non-intrusive

Easy to install

Remote calibration

Long battery life

Maintenance free

Patented technology

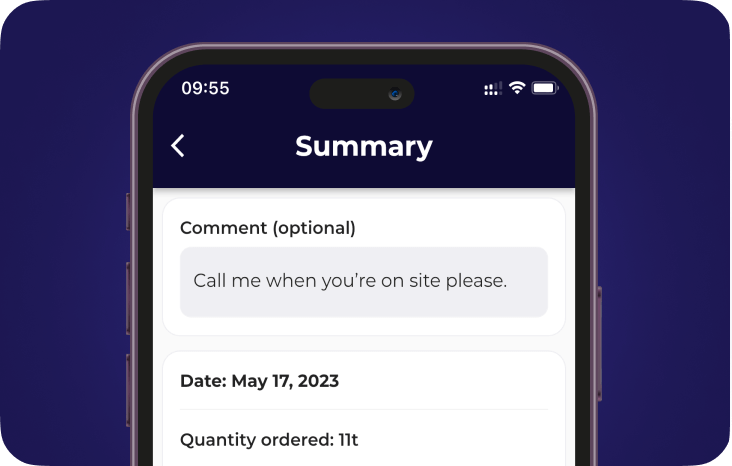

Real-time monitoring directly on your smartphone

Push notification

Real-time data

Forecast (D+4)

Ordering tool

Additional advanced monitoring from your office

Upgrade your experience with our ergonomic web-based platform. Discover multiple features, enjoy advanced filters, historical data, interactive maps and program alerts. No need to download software. Enjoy unlimited user access online. You can also easily integrate our data with your existing system through an API.

The same features as on mobile, but also:

Filters

Alerts setup

Access management

API Integration

Request a demo

Support

Premium customer support: your success, our priority

No matter where you are (on the farm, in the office, on the go) or what the situation is, we are just a call, message, or email away! From installation to daily use of our solution, our team of experts is with you every step of the way. BinConnect was developed hand in hand with you, our valued customers, and your feedback has shaped our customer-centric approach.

Benefits

The reasons why our users choose BinConnect

Why feed suppliers rely on BinConnect

Safety

From installation to daily inventory management, forget about climbing on feed bins, everything is done at ground level

Ease of use

From large-scale deployment to data visualization anywhere, everything has been designed to simplify your life

Efficiency

Save money, optimize your resources and improve your delivery routes by anticipating your customers' needs

Customer support

You are never left on your own, we assist you from the initial installation and throughout your daily usage.

Why farm managers rely on BinConnect

Serenity

No more feed shortage, your animal will always have the right quantity of feed at the right time

Safety

Forget about climbing to the top of the feed bins mostly in bad weather conditions and save valuable time

Non-intrusive

The sensor is installed outside the feed bin tank and on a single leg regardless of its shape

FAQ

Everything you need to know

- Sensor

- Interfaces

- Installation

- General

Absolutely, our solution is 100% wireless. There is no need for any specific cable work or connections. The electronic part of our device, along with the mechanical components, operates autonomously on a replaceable battery. Moreover, we offer various sensor versions to address any connectivity issues. These sensors use a multi-operator cellular network to transmit data or, in the absence of a cellular network, a 0G (low-power) network version is available for seamless data transmission.

No matter if it is a plastic or metallic one, as long as your feed bin is set on legs, in good conditions, our sensor can be quickly and easily installed. The chosen leg should firmly rest on the ground, be well-maintained, shielded from excessive sunlight, not used for filling the bin and not cluttered. A simple procedure and installation video are available, as well as online support by e-mail, telephone or even WhatsApp with our team if required.

With our special kit, installation is quick and easy, it takes less than 20 min to install a sensor. And only one sensor per feed bin is required.