Turn your simple plastic IBCs into a smart and connected container fleet

Request a demo

Business challenges

Are you dealing with inventory shortages, quality control or IBC recycling challenges?

Empty IBC

Urgent orders

Lost or inactive IBC

Quality control

How are you supposed to recycle your IBCs if you don't know where they are?

Solution

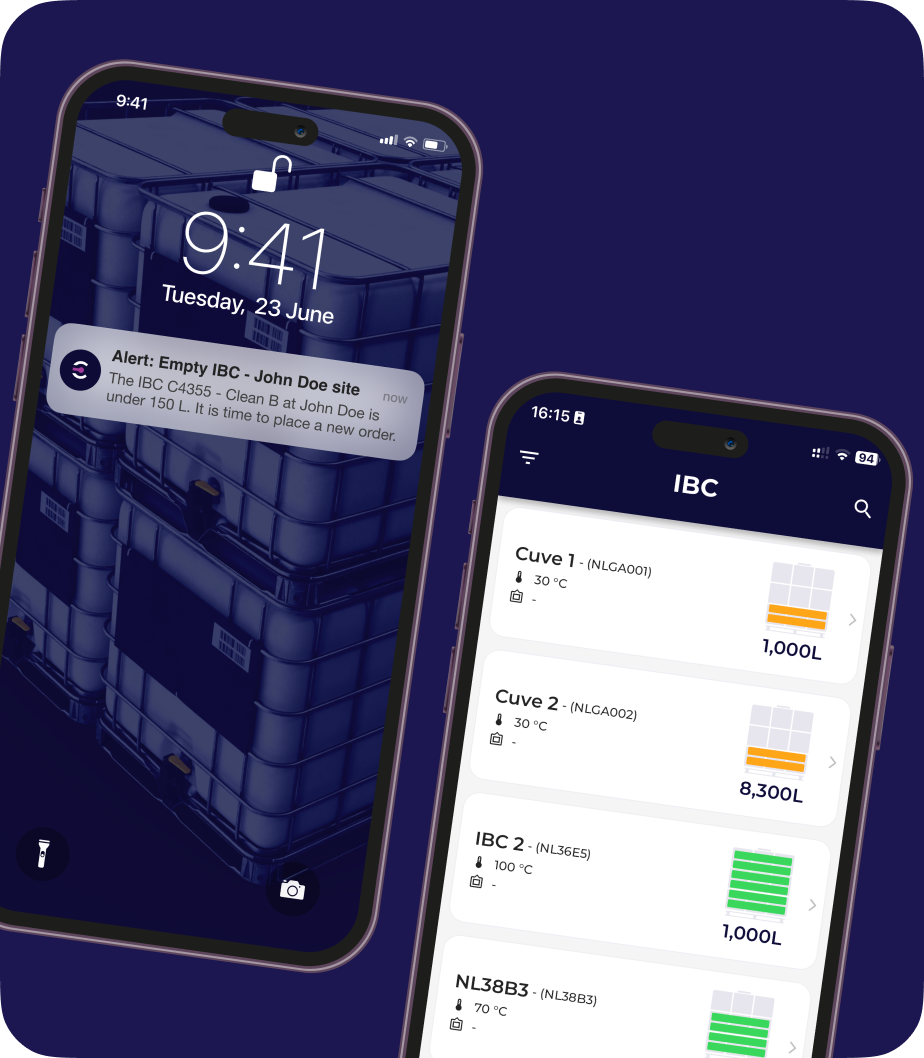

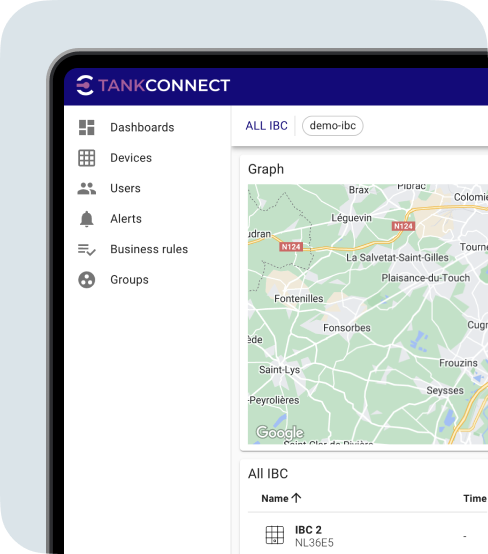

All your IBC fleet at your fingertips

Implementation

Make IBC monitoring and recycling easier with TankConnect

Non-intrusive and 100% wireless

Non-intrusive

Easy to install

Remote calibration

Shock & chemical resistant

Maintenance free

Patented solution

Instant visibility of key data

Fill level

Forecast

Temperature

Geolocation

Geolocation

ERP Integration

Request a demo

Support

Tailored and optimized customer support to meet your needs

Benefits

Why our users choose TankConnect

Why IBC manufacturers trust TankConnect

Innovation & customer loyalty

Stand out from the competition by choosing TankConnect. Our advanced solution goes beyond basic level monitoring, providing you with real-time access to temperature and geolocation data. Deliver exceptional support to your customers while ensuring the highest standards of storage conditions.

Circular Economy

Our solution empowers IBC manufacturers to play a pivotal role in sustainability. By implementing our system, you can maximize the lifespan of IBCs, reduce waste, and promote resource efficiency. Join the circular revolution and transform one-way IBCs from disposable waste to sustainable assets.

Why product distributors trust TankConnect

- Being able to geolocate containers at our customers' sites at any time, allowing us to optimize their turnover and, consequently, their profitability.

- Installing sensors regardless of the type or supplier of packaging.

- Easily using the platform and tracking KPIs.

In three words, my opinion is 'truly a plus'."

Visibility

No more manual monitoring, gain complete control and visibility over your IBC fleet with TankConnect. Locate empty containers, access real-time inventory and storage conditions, optimize delivery routes, and streamline operations for maximum efficiency.

Quality

Safeguard sensitive and hazardous chemical products with our solution. Continuous temperature monitoring and environmental tracking maintain product integrity, adhering to quality standards and providing peace of mind to distributors and customers.

Optimization

Avoid losses and improve your fleet management by tracking empty IBCs effectively. Anticipate customer needs and optimize your delivery routes with fully loaded trucks. Boost cost-effectiveness and customer satisfaction, leaving losses behind.

FAQ

Everything you need to know

- Sensor

- Interfaces

- Installation

- General

The calibration process is carried out remotely and automatically, eliminating the need for physical adjustments.