Donnez une nouvelle dimension à vos IBC en plastique en les connectant

Demander une démo

Enjeux financiers

Faites-vous face à des ruptures de stocks, problèmes de contrôle qualité ou du recyclage des IBC ?

IBC vides

Commandes urgentes

IBC perdus ou inactifs

Gestion de la qualité

Comment pouvez-vous assurer le recyclage de vos IBC si vous ne savez pas où les trouver ?

Solution

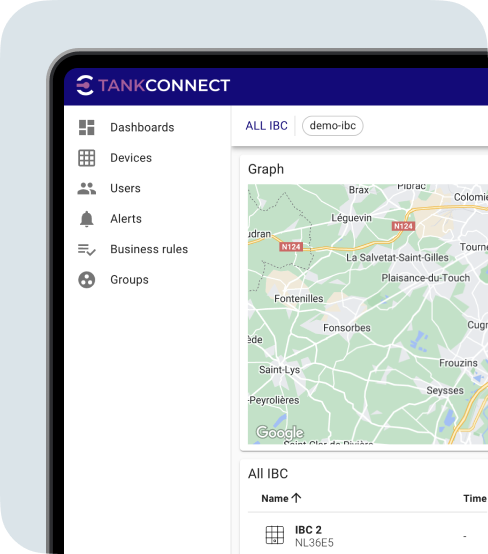

Tous vos IBC à portée de main

Mise en oeuvre

Simplifiez la gestion et le recyclage des IBC avec TankConnect

Non intrusif et 100% sans fil

Non intrusif

Simple à installer

Calibration à distance

Robuste (PEHD)

100% sans fil

Solution brevetée

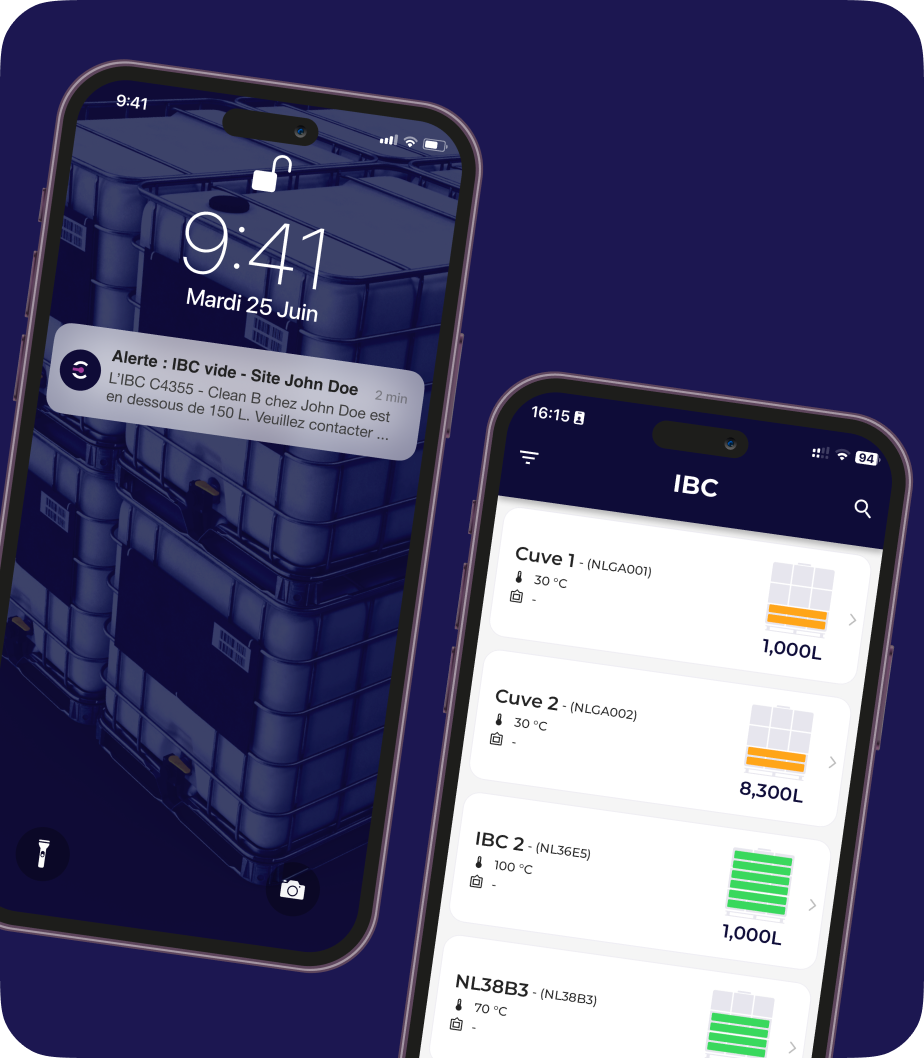

Accès à vos données clés en temps réel

Niveaux

Prévisions

Température

Géolocalisation

Alertes automatiques

Intégration ERP

Demander une démo

Service client

Une assistance sur mesure pour répondre à vos besoins

Bénéfices

Les raisons pour lesquelles nos utilisateurs choisissent TankConnect

Pourquoi les fabricants d'IBC font confiance à TankConnect

Innovation & fidélisation client

Démarquez-vous de la concurrence en choisissant TankConnect. Plus qu’un simple capteur de niveau, vous pouvez également contrôler les conditions de stockage avec un accès en temps réel à la température et la géolocalisation. Offrez un service client d'exception tout en leur assurant les meilleures conditions de stockage.

Économie circulaire

Réduisez votre impact écologique et jouez un rôle clé dans le développement durable de l’industrie avec notre solution innovante. En adoptant notre système, vous prolongez la durée de vie des IBC, réduisez les déchets et favorisez l'optimisation des ressources. Participez à l’économie circulaire et transformez les IBC à usage unique en actifs durables.

Pourquoi les distributeurs de produits font confiance à TankConnect

- Pouvoir géolocaliser les contenants chez nos clients à tout moment, ce qui nous permet d’optimiser leur turn-over et donc leur rentabilité.

- Installer les capteurs quel que soit le type et donc le fournisseur de packaging.

- Utiliser facilement la plateforme et suivre les KPI’s.

Mon avis en 3 mots : « Réellement un plus »."

Visibilité

Avec TankConnect, fini le suivi manuel, ayez une visibilité complète sur votre parc d'IBC. Localisez les conteneurs vides, accédez à l'inventaire et aux conditions de stockage en temps réel, optimisez vos tournées de livraisons et rationalisez vos opérations pour une efficacité maximale.

Qualité

Préservez l'intégrité des produits chimiques sensibles et dangereux grâce à notre solution. Le suivi continu de la température et la traçabilité des IBC permettent de respecter les normes de qualité et offrent une tranquillité d'esprit aux distributeurs et aux clients.

Optimisation

Ne subissez plus de pertes, optimisez la gestion de votre flotte et anticipez les besoins de vos clients en suivant efficacement les IBC vides. Boostez votre rentabilité et la satisfaction client en optimisant vos itinéraires de livraisons avec des camions pleins. Laissez les pertes derrière vous et visez l'excellence.

FAQ

Tout ce que vous devez savoir

- Capteur

- Interfaces

- Installation

- Autres

Vous n’avez besoin d’aucun outil pour calibrer physiquement le capteur, tout se fait à distance et automatiquement.

C’est parti !

Découvrez comment optimiser la logistique de votre chaîne d’approvisionnement

Demander une démo